Welding is a fabrication technique whereby two or more parts are fused by applying heat, pressure, or forming a joined appearance. You are looking for what gas is used for TIG welding so, as the TIG Welding is where inert gases, most often argon, and tungsten electrodes are used for fusion.

What is a TIG Welding?

TIG welding (tungsten inert gas welding), also called GTAW (Gas Tungsten Arc welding) and Heliarc Welding.

TIG welding needs a handheld tungsten electrode to produce the arc. Tungsten has a fairly high melting point when tungsten melts, so it doesn’t become a part of the weld.

Unlike MIG welding the electrodes become consumable during the welding process. In TIG Welding, the filler metal is added to the weld pool by the other hand (except in cases where its fed by the machine or robotic applications).

TIG welding’s benefit is that it gives tremendous control of the welding process and is typically very clean. The TIG welding method is very identical to gas or oxy-acetylene welding.

Also Check Best Welding Gloves

What Gas is Used in TIG Welding?

In the TIG welding process, the first step is to construct an arc between a sharp tungsten electrode and the work piece in an inert setting of argon or helium.

The pointed electrode’s tiny intense arc is favourable for high quality and accurate welding as you might know that the electrode is not consumed during welding.

So there is no need to balance the heat input from the arc when the metal is deposited from the melting electrode. When the filler metal is imposed, it is suggested to introduce it separately in the weld pool. Now lets move to why we actually need a shielding gas.

What Shielding Gas Is Used For TIG Welding?

The main objective of shielding gas is to protect the weld from the unwanted effects of the atmosphere, usually from oxidation and nitrogen absorption. These factors influence the stability of the arc

What are the Different Shielding Gases?

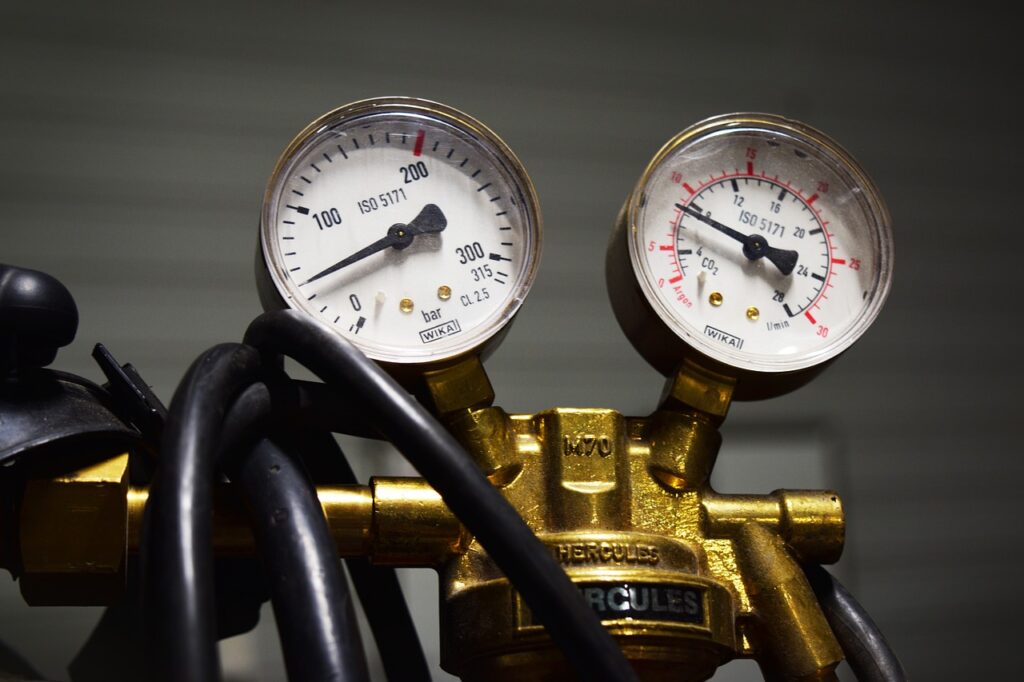

When we talk about welding gases, shielding gases are used worldwide in MIG and TIG welding to preserve welds from oxygen and water contamination in the atmosphere. Water and oxygen can cause a substandard quality weld and make the welding process more difficult for the welder. There are two categories: inert and active gases.

- Inert Gas – Inert gases have no impact or outcome on the weld as it’s an inert gas.

- Active Gas – An Argon/CO2 blend is supposed to be an active gas because it contains Carbon Dioxide. The presence of Carbon dioxide results in electrical conductivity highly affects the voltage of the arc and improves penetration.

The following gases are widely used:

Argon

It is the most commonly used shielding gas used for steel, stainless steel, aluminum, and titanium.

Argon with hydrogen

The addition of hydrogen to argon will make the gas slightly reduced, facilitating cleaner good welds without surface oxidation.

When the arc is more constricted, it promotes higher welding speeds. The cons include hydrogen cracking in carbon steels and weld metal porosity in aluminum alloys.

Helium and Argon Mixtures

The addition of helium to argon will cause an increase in the temperature of the arc. This results in higher welding speeds and deeper weld penetration.

Helium and argon mixtures are not so budget-friendly. Plus, it’s a bit difficult to obtain the desirable arc.

Things to Keep in Mind while the TIG Welding is in The Process…

If your weld requires it to be presentable without post-weld operations, you’ll need a welding technique that permits for a smoother weld. You need to keep this in mind.

When welding articles are protected, or the weld bead is enabled to be put forward and somewhat rough, then MIG welding will be perfectly sufficient.

You May Also Like best budget TIG welder

Why should you not use the same gas for MIG and TIG welding?

Here are a few reasons, listed below:

- TIG welding primarily employs inert gas for a neat finish and no oxidation, while if an inert gas is used entirely for MIG welding, it could spoil the view of the finished weld.

- MIG welding can withstand semi-inert gas, as it assists with the welding process. However, semi-inert gas has a destructive effect on the TIG weld.

- TIG welding goes with very few gases, while the MIG welding process can manipulate several different gases and mixtures of inert and semi-inert.

TIG Welding Gas for Mild Steel

Mild steel is a type of steel with less carbon ranging from 0.05% to 0.25% of the composition, based on weight. However, mild steel is not alloy steel, so it does not contain big amounts of other components besides iron.

Mild steel is typically the initial metal that a new welder educates on due to its comfort in welding. Still, the TIG process needs more concentration than inert metal gas (MIG) welding or oxy-acetylene torch welding. Before welding mild steel, all workpieces and even the welding rod must be cleared.

To ensure the absence of any particulates which can weaken the weld. For thinner sheets, the filler material may not be required. The welder strikes an arc at the start of the weld while holding the electrode at angles ranging from 10- to 15 degrees.

The electrode is employed in the weld’s direction, and the welder “pushes” the molten metal forward by moving the electrode and the arc forward.

The welder must maintain close contact between the electrode, the workpiece, and the filler rod. It should be kept into consideration that the filler rod touches the electrode.

The illumination supplied by the TIG welding process is not as brilliant as other welding methods. Tig welding gas for mild steel needs an apt referring.

Still, TIG welding bears a higher percentage of ultraviolet light than other methods, so extra safety measures have to be taken by welders to safeguard their workspaces. Welders should try a lens for safety.

With all welding techniques, a welder should wear gloves and cover the skin through an apron. Or coveralls to protect from burns. TIG welding produces no sparks, so welders are enabled to choose the most suitable welding position.

Also Check Out best welding cart

Conclusion

We want you to know that the kinds of gases you utilize as shielding gas play a major role in your weld’s success.

To choose the right gas for TIG welding and mild steel supply. Take advice from the welding engineers for guidance and recommendations to enhance your performance.